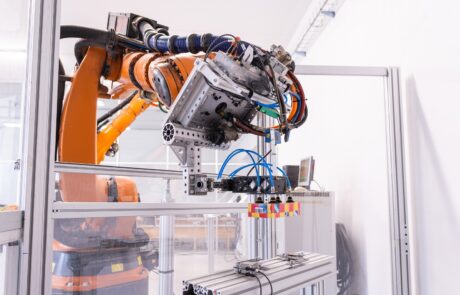

Robotive s.r.o. was founded for the purpose of programming industrial robots and PLC systems. The company provides its business partners with solutions in the field of industrial automation, which, in addition to programming, also include the basic parameterization and calibration of robots, recovery and commissioning, the optimization of processes in terms of quality and production cycles, etc.

We strive for the quick but efficient executions of tasks to develop robotic power in the production of modern automobiles. The quality and reliability of our services are proven by the successfully completed projects, where client satisfaction is our first priority.

Our offer:

Online programming of KUKA, ABB and FANUC industrial robots

Offline programming of industrial robots in PROCESS SIMULATE

Our offer:

Online programming of KUKA, ABB and FANUC industrial robots

Offline programming of industrial robots in PROCESS SIMULATE

2023

AUDI Győr

- AUDI Q3 – SEITENTEILE, AUFBAU, UNTERBAU, DACH

- FANUC R-30iB+ VASS Standard

- Schweissen (Bosch), Kleben (Atlas Copco), Handling

2021

PORSCHE Leipzig

- PORSCHE MACAN – AUFBAU

- ABB IRC5 VWRS VASS Standard

- Laserschweissen (Laserline, Scansonic), Schweissen (Bosch), Kleben (SCA), Vision (Zeiss), Nieten (Böllhoff), Schrauben (Weber), Rollfalzen (Engrotec), Buersten (Ferrobotics)

2020

ŠKODA Kvasiny

- ŠKODA KAROQ – DACH

- KUKA VKRC4 VW VASS Standard

- Kleben (SCA), Vision (Sick), Blindnieten (Böllhoff), MIG (Fronius)

Development of youth, sports and education

The company Robotive s.r.o. is not opposed to cooperation with secondary schools and organizations that contribute to the education of children and youth. We are happy to cooperate with our partners: